Services

Benefit from our field experience with our Engineering, Commissioning, Technical Support, Consulting, and Training services.

Engineering and Commissioning

Engineering

With our engineering services, we provide comprehensive solutions for the communication architecture and topology of energy plants. We offer EDAŞ SCADA support, remote assistance, and retrofit services for interrupted processes, helping our customers effectively benefit from developments in the energy sector.

Commissioning

With our Technical Support team, we configure hardware and software configurations to meet the specific requirements of field environments. During this phase, we ensure that the equipment intended for use in energy production and consumption facilities is integrated correctly, enabling the efficient operation and smooth commissioning of the facilities.

What do we do during the commissioning process?

System Validations

We verify that all components in the facility are correctly installed and operating under suitable conditions. We check the compatibility of hardware and software components with the project requirements.

Performance Optimization

In the commissioning process, we facilitate fine-tuning and optimizing the system’s performance. We check the applicability of parameters, settings, and configurations to ensure optimal energy production and efficiency.

Functional Tests

In this stage, we conduct tests to ensure the proper functioning of monitoring and control functions. By experimenting with different variations, we aim to identify the most optimal conditions for commissioning the facility.

Occupational Safety and Expertise

Our expert technical team works to identify potential hazards in operations through our hardware and equipment. We aim to reduce the risk of potential breakdowns and accidents during system operation.

Regulatory Compliance

We ensure compliance with specific regulations related to remote monitoring, facilitating portfolio management with calculations and reporting in accordance with the IEC 61724-1 standard.

What do we do during the commissioning process?

System Validations

We verify that all components in the facility are correctly installed and operating under suitable conditions. We check the compatibility of hardware and software components with the project requirements.

Performance Optimization

In the commissioning process, we facilitate fine-tuning and optimizing the system’s performance. We check the applicability of parameters, settings, and configurations to ensure optimal energy production and efficiency.

Functional Tests

In this stage, we conduct tests to ensure the proper functioning of monitoring and control functions. By experimenting with different variations, we aim to identify the most optimal conditions for commissioning the facility.

Occupational Safety and Expertise

Our expert technical team works to identify potential hazards in operations through our hardware and equipment. We aim to reduce the risk of potential breakdowns and accidents during system operation.

Regulatory Compliance

We ensure compliance with specific regulations related to remote monitoring, facilitating portfolio management with calculations and reporting in accordance with the IEC 61724-1 standard.

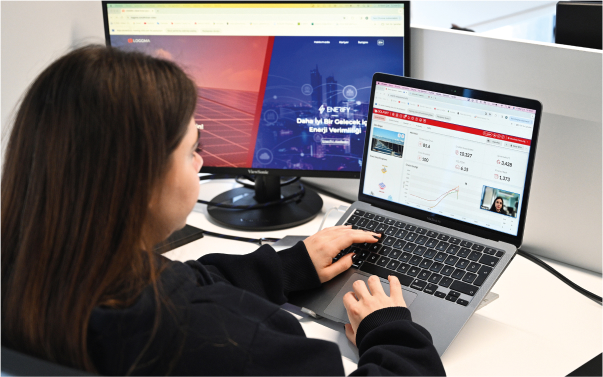

Technical Support

For any technical questions or issues you may encounter, our technical team is here to provide support, ensuring a smooth user experience for you.

Support Button Feature

We have a support button feature available to quickly provide solutions to any questions about our portal or hardware. This allows you to log support requests and create a history of all ongoing support processes, making it easier to track the progress of your requests.

Remote Support

In case of emergencies or when you need immediate assistance, you can request remote support. Our expert technical team will assist you as quickly as possible.

Consulting and Training

ConsultIng

Needs Analysis and Planning

We conduct a preliminary assessment focused on the type, capacity, and operation of your energy facilities to perform a detailed needs analysis and planning process. This helps determine areas where improvements are needed.

Site Survey and Data Collection

Following the planning stage, our expert team conducts site visits to observe the operational status of your equipment and collect data. During this phase, we perform detailed measurements to identify critical parameters such as energy production, equipment efficiency, and potential power losses.

Performance Analysis and Evaluation

Subsequently, in this stage, the data collected is analyzed and evaluated by our portals to assess the performance of your energy plants. Detailed analysis is provided on factors such as power generation, efficiency, and plant capacity. This allows you to identify the advantages and disadvantages of your existing systems.

TraInIng

Portal Training

At LOGGMA, we provide an innovative learning experience through training videos on Udemy, delivered by our experts, to help you specialize in the energy sector. Upon successful completion of LOGGMA-approved courses, participants receive certificates that not only validate their expertise in the industry but also enhance career opportunities.